ETS82 High-Speed Air-Leg Rock Drill (Tunneling & Mining Beast)

Why upgrade to the ETS82? The ETS82 Air-Leg Rock Drill is a new generation of high-speed pneumatic drilling machinery. Engineered specifically for railway, highway, and underground mine tunnel excavation, it is designed for one primary goal: Extreme Penetration Speed in medium-hard to hard rock (f=8-18).

🌍 The Next Generation Standard: Delivering a massive impact energy of ≥ 78 Joules, the ETS82 drills significantly faster than legacy models. Among air-leg drills of its class, it stands out for its optimized valve system, high efficiency, and deep hole drilling capability. It operates seamlessly with the FT160A pusher leg.

⚡ Compressor & Setup Requirements

Air Consumption: ≤ 88 L/s (approx. 186 CFM) @ 0.5 MPa

Recommended Compressor: Minimum 200–250 CFM per drill to unleash its massive 78J impact power.

Required Air-Leg: Must be paired with the FT160A telescopic air-leg for horizontal and inclined tunnel drilling.

Note: The ETS82 consumes more air than standard drills, but converts it into unparalleled drilling speed, dramatically increasing tunnel advance rates.

Model Comparison: ETS82 vs YT28

| Feature | ETS82 (High-Speed Series) | YT28 (Standard Series) |

|---|

| Impact Energy | ≥ 78 Joules (Massive) | ≥ 65 Joules |

| Cylinder Diameter | 82 mm | 80 mm |

| Penetration Rate | Ultra-Fast | Standard |

| Best Use Case | Time-critical tunneling projects | General underground mining |

Technical Parameters: ETS82 Rock Drill

| Parameter | Value | Unit |

|---|

| Weight | 26.5 | kg |

| Dimensions | 659 x 248 x 205 | mm |

| Cylinder Diameter | 82 | mm |

| Piston Stroke | 60 | mm |

| Working Pressure | 0.40 ~ 0.63 | Mpa |

| Impact Energy | ≥ 78 | J |

| Impact Frequency | ≥ 39 | Hz |

| Air Consumption | ≤ 88 | L/s |

| Torque | ≥ 26 | N·m |

| Drilling Diameter | 34 ~ 45 | mm |

| Max. Drilling Depth | 5 | m |

| Shank Size | H22 x 108±1 | mm |

Compatible Air-Legs & Oiler

| Model | Specification / Length | Weight |

|---|

| FT160A Air Leg | 1668 mm | 17 kg |

| FY250 Oiler | 0.25 L (Capacity) | 1.2 kg |

💡 Safer Than Dynamite? (The Drill & Crack System)

The ETS82 drills holes fast. But for breaking rock in underground mines without the toxic gas and explosion risk, switch to our safe chemical solution:

👉 High-Grade Soundless Cracking Powder (HSCA)

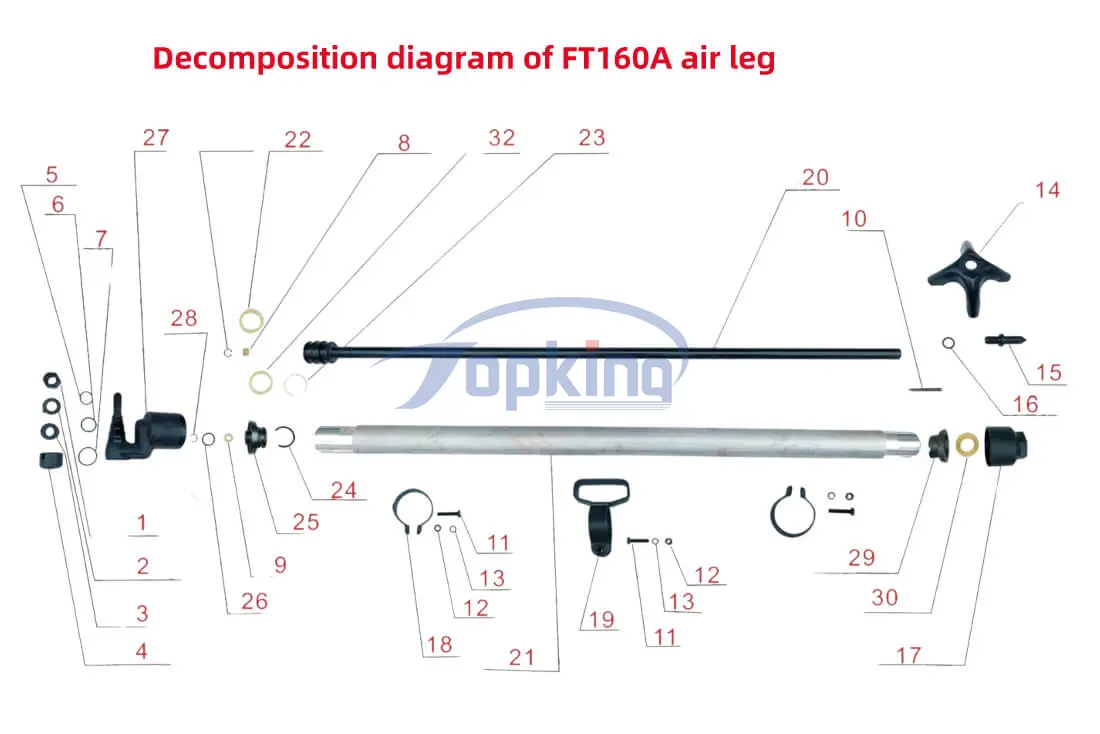

ETS82 & FT160A Parts & Accessories Diagram

Due to the extremely high impact energy of the ETS82, we supply a complete range of heavy-duty replacement parts for both the drill and the FT160A pusher leg to ensure zero downtime:

| Common Spare Part (English) | System / Function |

|---|

| Piston (82mm) | Main Drill: Delivers massive 78J impact force |

| Rifle Bar & Bronze Nut | Main Drill: Manages high-speed bit rotation |

| Coaxial Water & Air Tube | Main Drill: Provides central water flushing |

| Control Valve Assembly | Main Drill: Grouped backhead controls |

| FT160A Air-Leg Cylinder | Pusher Leg: Telescopic extension tube |

| Air-Leg Control Handle | Pusher Leg: Adjusts feed pressure and retraction |

| O-Ring & Seal Kit (Rubber) | Consumable: Prevents pneumatic pressure loss |

Matched Consumables & Drilling Tools

Operation & Safety Guidelines

1. Pre-Check: Ensure air/water lines are clear, the FY250 oiler is filled, and connections are firm before starting.

2. Roof Safety: Always check for and scale down loose rocks on the tunnel roof near the working face.

3. Wet Drilling Only: Strictly forbid dry drilling underground. Turn on water first, then air. Turn off air first, then water.

4. Starting: Run at low speed (partial throttle) to open the hole collar, then switch to full speed.

5. Posture: Maintain a safe standing posture beside the drill. Never apply your body weight; let the FT160A air-leg provide the thrust.

Frequently Asked Questions (FAQ) & Troubleshooting

Q: Can I use the ETS82 as a hand-held drill without the air-leg?

A: No. The ETS82 weighs 26.5kg and generates massive 78J recoil. It is specifically designed to be mounted on the FT160A pusher leg for horizontal or inclined tunnel drilling.

Troubleshooting: The drill penetrates slowly despite high air pressure.

A: If the compressor is delivering sufficient volume (≥ 200 CFM) but penetration is slow, check the pusher leg thrust. If the air-leg isn't pushing hard enough against the rock face, the impact energy is wasted. Also, check if the button bit is dull and needs grinding.

✔️ Factory Direct Supply | ✔️ Complete Tunneling Packages | ✔️ Fast Global Shipping

Get ETS82 Best Factory Price