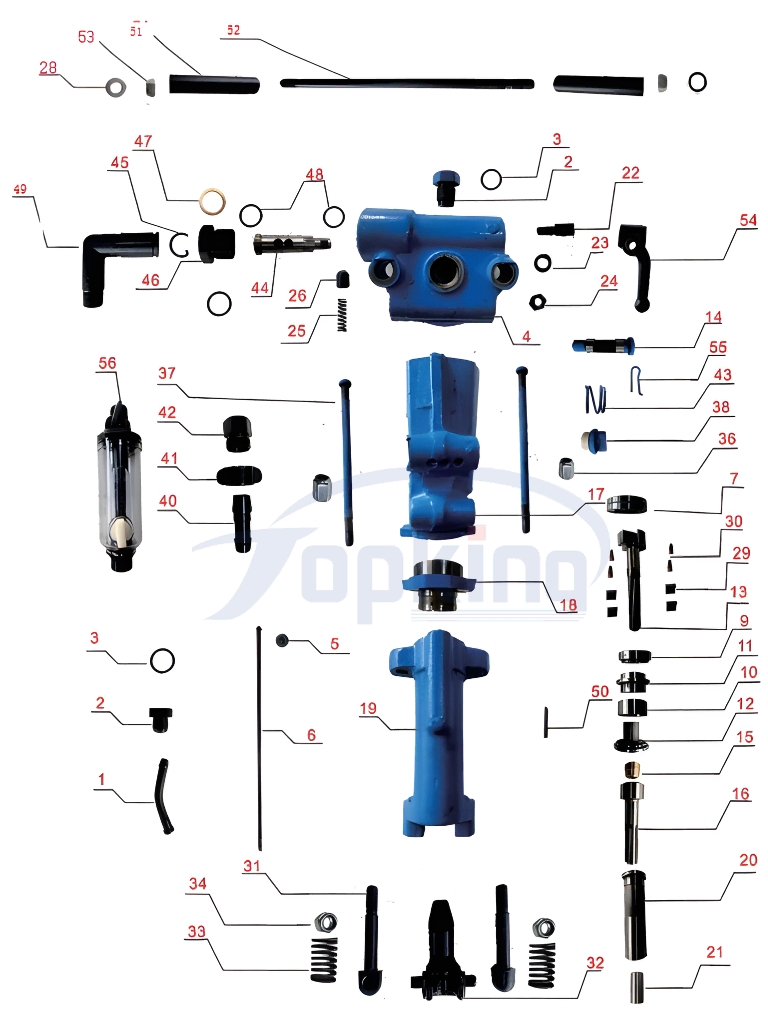

Y26 Hand Held Pneumatic Rock Drill (Jack Hammer)

The Y26 Hand Held Rock Drill is a lightweight yet powerful pneumatic tool, engineered for high-efficiency drilling in demanding quarrying applications. It is the preferred choice for drilling blastholes in medium-hard and hard rock (f=8-18).

Versatile for both dry and wet drilling, the Y26 is perfect for secondary blasting in mines, road construction, and civil engineering. As a professional mining equipment supplier, Topking (Expandag) offers the Y26 at a competitive factory price without compromising on quality.

(Y26 Rock Drill - Compact & Powerful)

Key Features & Benefits

● High Efficiency: Delivers powerful impact energy and high drilling frequency for fast penetration.

● Lightweight & Portable: At only 26kg, it is easy for a single operator to handle, reducing fatigue.

● Durable Construction: Built with forged steel components to withstand tough mining environments.

● Versatile Operation: Capable of drilling vertical, horizontal, and inclined blastholes.

Technical Specifications

| Parameter | Value | Unit |

|---|

| Weight | 26 | kg |

| Dimensions (L×W×H) | 650 x 534 x 125 | mm |

| Cylinder Diameter | 65 | mm |

| Piston Stroke | 70 | mm |

| Working Pressure | 0.4 | Mpa |

| Impact Energy | ≥ 30 | J |

| Drilling Frequency | ≥ 23 | Hz |

| Air Consumption | ≤ 47 | L/s |

| Drilling Diameter | 34 ~ 42 | mm |

| Drilling Depth | Up to 5 | m |

| Shank Size (Hex) | 22 x 108 | mm |

| Optional: FY200 Oiler | Value | Unit |

|---|

| Weight | 1.2 | kg |

| Oil Capacity | 0.25 | L |

💡 Recommended Usage

Use Y26 Rock Drill to drill holes, then fill them with Expandag Soundless Cracking Agent for silent demolition.

This is the most efficient method for granite and marble quarrying.

Accessories Included

Safety Guidelines

1. Pre-Drilling: Check integrity of all parts, lubricant, and hose connections.

2. Wet Drilling Only: Turn on water before air. Turn off air before water. Avoid dry drilling to prevent dust.

3. Correct Operation: Start slow to stabilize the hole. Do not use your body weight to force the drill.

Get a Free Quote for Y26